WEATHERITE LAUNCHES WISPAIR RANGE OF AIR HANDLING UNITS

Using specially developed selection and quotation software, integrated with a purpose designed interface programme, which seamlessly links design, purchasing and manufacturing processes, Weatherite’s new WispAir range of standard/modular AHUs combine a rapid quotation turnaround with fast-track delivery of a range of innovative, energy efficient, fully compliant Air Handling Units.

Weatherite has responded to the industry’s requirement for quick turnaround of quotations and a competitively priced, quality ‘finished product’ and has spent the last 12 months developing their ‘WispAir’ AHU range- to specifically match the industry’s fast-track requirements.

As Steve Cartledge, Weatherite’s sales director explains: “lead times are getting shorter and there will always be increasing pressure on costs. The challenge for us was to design, build and deliver, quality, energy efficient, fully compliant AHU’s that meet the client’s exact requirements-within the shortest possible time- and at the right price. We’ve done our homework and have spent some considerable time developing our quotation software and manufacturing systems and we know we can compete in this market-having won a number of major orders recently”.

“Exceptional efficiency is also key to delivering the best Air Handling Units and Weatherite has applied this principle to every stage of the process from quotation to production and ultimately to the energy consumption of the finished product”.

The WispAir range covers typical air flow rates from 0.3m3/s to 35m3/s however, Weatherite can deliver AHUs in any specific size/configuration, quickly and competitively.

WispAir offers an extensive range of configurations to suit each individual application and can even supply units in multiple sections or as a flat-pack solution, to suit dimensional/access constraints.

All WispAir AHU’s are fully ErP compliant (the EU directive aimed at improving the energy efficiency and other environmental performance criteria for related products) and incorporate the very latest technology, delivering exceptional performance, reliability and energy efficiency. Utilising high efficiency fans and motors and incorporating the latest heat-recovery technology, the WispAir range delivers an exceptionally quiet, compact, cost effective solutions for small, medium and large applications.

The WispAir range further enhances Weatherite’s extensive range of HVAC solutions.

Trainee Telecoms Account Engineer

Working within the Telecoms Sales Team, this position will receive training to:

- Undertake site surveys

- Prepare and submit customer quotations

- Maintain and deelop existing customer accounts

Please note that this is not an apprentice position and does not involve day release.

Candidates should be numerate, computer literate, have good communication skills and be able to work well with the other members of a busy team.

Experience of working within a similar environment would be beneficial but attitude and a desire to succeed is consider more important.

Due to site requirements the successful applicant must be at least 18 years old.

A full driving licence is also required as the position will involve travel. It will also involve working hours over and above the standard working hours on occasion and also occasional overnight stays.

Industrial Electrician

2 x Industrial Electrician.

To carry out wiring and electrical installation and testing of HVAC units.

Must be fully qualified, including 17th edition.

Must have experience in HVAC, ideally in a similar environment

An inspection & test qualification would be beneficial

Marks & Spencer praises Weatherite's replacement Chillers at Kensington store

Leading manufacturer of air conditioning solutions, Weatherite Air Conditioning Ltd, has designed, manufactured and installed two new Chillers at a Marks & Spencer store in Kensington, London.

The contract included the replacement of two 15 year-old York Chillers, which had reached the end of their useful life. The two new Weatherite Chillers were designed and pre-assembled at Weatherite’s manufacturing facility, dismantled and then re- built in situ onsite in a small internal plantroom at the busy London Kensington store.

Synergy Building Services Consultancy was employed by M&S to design the system and to calculate the installed cooling requirement at the store. Synergy then produced a scope of works to tender the replacement of the Chillers.

Synergy’s project consultant, Peter Simms, said: “We faced a number of hurdles with this job and Weatherite was the only company that developed a technical design solution that met those challenges.

“The old Chillers were externally mounted and needed a very high degree of attenuated barriers around the sides and over the top of the plant area which further added to airflow and fan power consumption.

“Synergy calculated the new store cooling load to be 1000 kW. In fact, the store needed an extra 300kw cooling over and above what the old Chillers were providing. As a result, Weatherite designed two new Chillers at 500kW capacity each to meet the new design duty.”

The existing two multi-cylinder, semi hermetic compressor chillers had to be dismantled in situ and taken through the building, piece by piece. Once the existing chillers had been dismantled, the existing framework was refurbished and modified to house the new air-cooled condenser coils and high efficiency EC Fans. Due to the very stringent noise constraints on-site, the condenser EC fans were fitted with AxiTops Diffusors for improved airflow and reduced noise levels. This all contributed to the new Chillers having a much lower noise levels than the existing Chillers without the need for attenuation to be refitted around the new Chiller plant.

The new Chillers were also supplied with new control panels and a Siemens control system integrated onto the existing BMS system.

The design and installation has been praised by Marks & Spencer’s programme manager, Paul Jenkins who said: “The design and engineering of the kit is absolutely superb and we were really pleased with the implementation of the project”.

When Marks & Spencer started the process of replacing the old water chillers, the team faced many challenges, particularly planning permission constraints and the length of time the project was going to take.

“So we worked with Weatherite to come up with a plan. Instead of building on the roof externally we would transport all the cooling kit internally into a plantroom within the store, the main advantage of this was that the process didn’t disrupt customers”, said Paul.

Building chillers on site in a small area took a huge amount of planning. The cooling equipment had to be transferred in pieces via a goods lift and every component had to be measured at Weatherite before bringing onto site- to ensure it could be transported through the store.

Weatherite Air Conditioning’s key account executive, Paul Ludlow, said: “The sequence of dismantling the old chillers and building the new plant, both within the internal plantroom and externally, had to be synchronised to avoid affecting store operation. We had to keep the existing Chiller No 1 running until we were able to decommission and replace that too.”

Weatherite also replaced the existing circulation pump with a twin head circulation pump to ensure resilience with the new installation allowing for some standby capability.

Marks & Spencer’s Paul Jenkins continued: “The old system incorporated a four-compressor system that basically ran the cooling of the store. This was risky because if we lost one compressor we lost a quarter of the store’s cooling capacity.

“We’ve now put in place 16 screw compressors, so if we lose one, we only lose a 16th of the overall capacity. Meaning we’ve now got a lot more resilience.”

As well as designing, manufacturing and installing the chillers, Weatherite Service & Maintenance (Weatherite Air Conditioning’s sister company) is responsible for its upkeep of the equipment, which legally has to be maintained every six months.

Weatherite wins prestigious supplier award

UK leader of made-to-measure air conditioning equipment, Weatherite, has been awarded the silver award at the Bouygues Supply chain event.

The award received by WACL’s sales director, Steve Cartledge, at the Bouygues Energies & Services (E&S) annual supply chain even, is based on supplier evaluation and is judged on a strict criteria based around environment, health and safety, quality, leadership and commercial aspects. The data is updated monthly and also puts an emphasis on consistency.

Weatherite scored very highly and achieved 88 per cent, just three per cent off the gold.

On receiving the award Weatherite Air Conditioning’s sales director, Steve Cartledge, said:

“We were delighted to attend and winning this prestigious award is the icing on the cake. It is a great event, which offers companies like ours the opportunity to interact and engage with the Bouygues procurement team and other supply chain members, sharing information, ideas and examples of best practice.”

Packaged plant rooms at Raigmore Hospital, Inverness

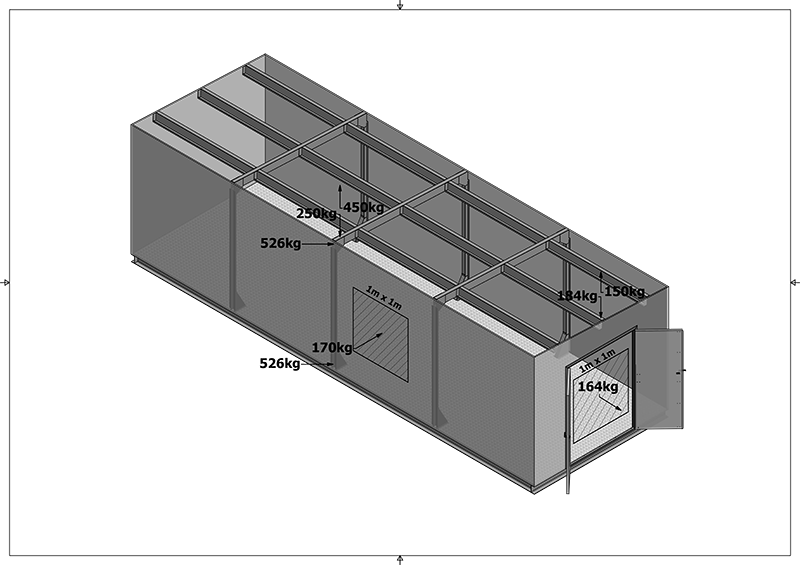

This was an unusual project to supply two AHUs to provide ‘controlled’ conditions in isolation rooms at a hospital in Inverness, Scotland. What makes the project interesting is that the units would normally have been mounted within a building plantroom but there was nowhere in the building to install them. Weatherite therefore had to design a solution to meet stringent building regulations and ensure the systems could be maintained without the risk of personnel coming into direct contact with contaminated filters.

THE SOLUTION

Weatherite designed a bespoke weatherproof plantroom enclosure to house the two very large AHUs, so it could be lifted onto the roof for ease of maintenance. The plantroom was built to meet stringent BS6399 part 2&3 and BS5950 part 1 building regulations and had to undergo stringent factory tests prior to dispatch. These tests were carried out by structural engineering experts, Fairhurst, Inverness and were undertaken to simulate wind pressures and snow loads on the sides and roofs of the plantrooms. As the plantroom was categorised as Buildings, this was a mandatory requirement for Scottish Building Regulations.

Both units at Raigmore Hospital provide 100 per cent run and standby capability and can be swapped over in operation during maintenance and service work to ensure continuity of room conditions at all times. The design incorporated a number of elements essential in ensuring isolation of contaminated air, including negative air pressure, bespoke high efficiency filtration systems and high grade H10 HEPA filters.

The air handling system also included a ‘bag in, bag out’ arrangement for removing contaminated particulate filters and gas absorbers in hazardous environments. With this system, FM maintenance personnel are protected from coming into direct contact with the interior of the housing and hazardous containments during filter change-over. Other features include low-temperature hot water heating coils, integral DX cooling, with scroll compressor, and condenser heat rejection in exhaust pat, smoke rated exhaust fans and a separate extract system.

Weatherite hails success of apprenticeships and promotes key staff

Leading air conditioning service and maintenance company, Weatherite, is pleased to announce two promotions within its contracts and administrate departments, as the company prepares to expand its operations to support its growing customer base.

Weatherite Service and Maintenance (WSML) has promoted Aaron Ludlow, one of its long serving trainees from service engineer to installation contracts engineer.

Aaron, 23, who won the ACR Journal ‘Trainee of Year’ Award in 2013, joined the company nearly seven years ago and has gone from strength-to-strength. He started with the company as an apprentice service engineer and excelled in his two-year long Level 2 Air Conditioning and Refrigeration course, which helped him to develop the practical skills and knowledge essential to working in the industry.

Aaron then became a full-service engineer, primarily working in the Projects team. His training has continued and for the past two years has worked on major telecom sites including BT, Everything Everywhere (EE) and Virgin Media, ensuring all systems and components are designed, installed, tested, operated, and maintained.

Aaron’s new responsibilities will include site surveying, producing quotations and liaising with sub-contractors who carry out work on various sites including one of WSML’s main contracts, Tesco.

“Weatherite is fully committed to the apprentice scheme, which we view as an integral part of the Company’s proud links with the local community, and Aaron is proof that, managed well, Apprenticeship’s provide a win – win situation for all concerned,” said Ricky Brookes, director, WSML.

“Aaron is a committed team player and we are delighted with his progress. We hope that he will be an inspiration to this year’s apprentice intake.”

The company has also promoted its operations and estimator, Kirsty Bunn, to assistant manager. Kirsty, 31, will manage the BT contract and has recently began work on the company’s key Tesco account. She will also provide quoting on smaller jobs at the company’s accounts including BT, M&S and John Lewis. Kirsty will also oversee the day-to-day running of the office and will assist office manager, Kerry Powell, in her role.

“Kirsty joined us six years ago as a co-ordinator and is an excellent member of our team. We congratulate her in her new role,” added Ricky Brookes.

In another development, WSML has hired a new apprentice service engineer. Curtis Whalley, 19, takes over from former apprentice, Rhys McDonald who achieved a top six finish in the 2017 ACR Journal “Trainee of the Year” Awards. Rhys now works full-time as a service engineer following his apprenticeship programme at Weatherite.

WSML is the oldest operating company within the Weatherite Group, Weatherite Service & Maintenance opened its doors for business in August 1972 and is now one of the UK leaders in the servicing and maintenance of all aspects of heating, ventilation and air conditioning (HVAC) systems.